-

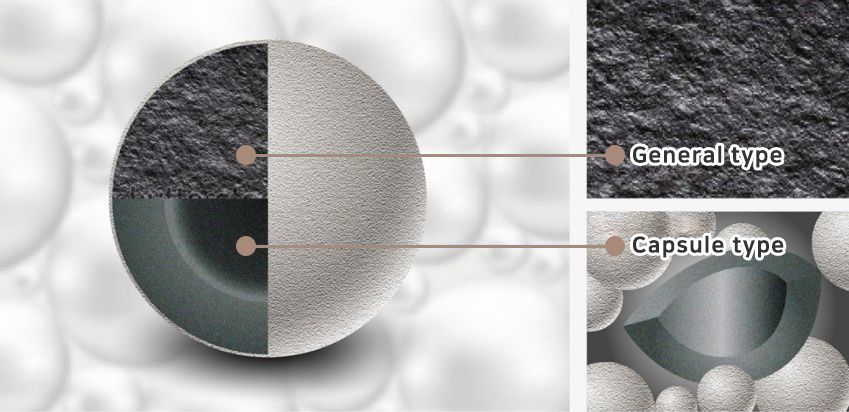

Fill up the F.I(Front Injection) spherical powders with active ingredients. They dissolve at pH 4.2~6.4, so the absorption rate of the active ingredients become higher.

-

The complete Wet Coating Technology allows the powder to hydrate the skin throughout the day.

-

Feeling of comfort, just as the skin is allowed to breathe.

-

Solving the shortcomings of powder. The one and only powder in Korea, with ZERO SKIN DRYNESS! ERO CAKEY! ZERO CREASING!

-

Since it is allowed to choose active ingredients (such as hyaluronic acid), it is possible to come up with various products with a variety of functions.

-

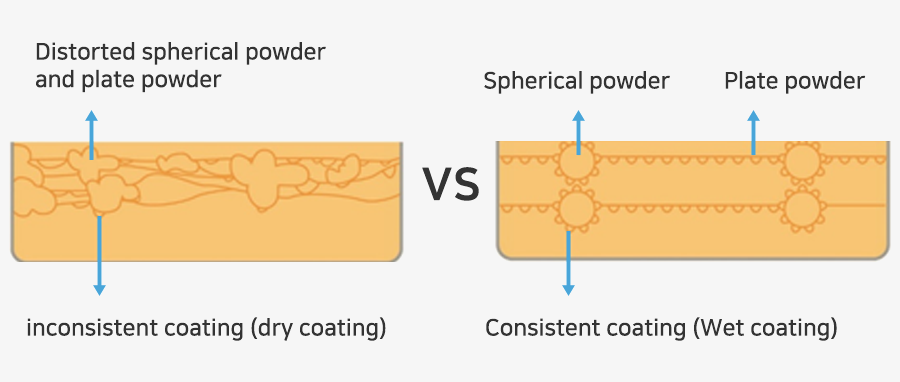

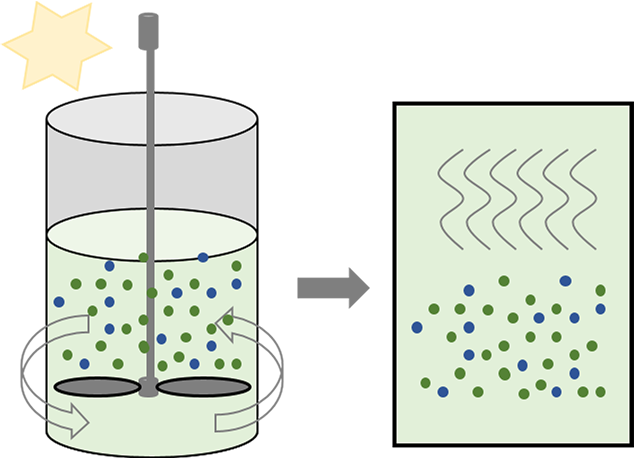

Wet CoatingADD THE MIXED POWDER TO A KILN AND MIX IT WITH SKIN-MOISTURIZING INGREDIENTS AND ALCOHOL TO MAKE IT A LIQUID AND THEN, DISPERSE IT AT HIGH SPEED.

Wet CoatingADD THE MIXED POWDER TO A KILN AND MIX IT WITH SKIN-MOISTURIZING INGREDIENTS AND ALCOHOL TO MAKE IT A LIQUID AND THEN, DISPERSE IT AT HIGH SPEED.1. Since they are liquid while mixing, moisturizing ingredients are evenly and lightly attached onto the powder.

2. When alcohol becomes evaporated, only the powder and moisturizing ingredients remain.

-

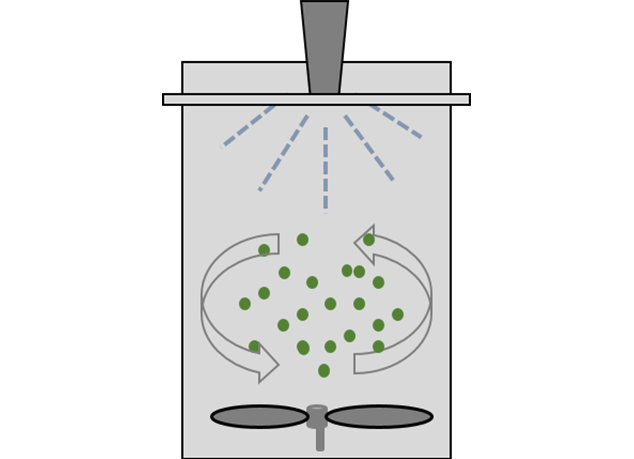

Dry CoatingIT REFERS TO THE METHOD OF SPRAYING SKIN MOISTURIZING INGREDIENTS ( ● ) FROM ABOVE WHILE MIXING THE POWDER ( – – – ) IN A BLENDER.Since the power’s flow is not constant, the sprayed ingredients become stick onto the wall of the blender, or too much or too less the ingredients become attach to the powder.

Dry CoatingIT REFERS TO THE METHOD OF SPRAYING SKIN MOISTURIZING INGREDIENTS ( ● ) FROM ABOVE WHILE MIXING THE POWDER ( – – – ) IN A BLENDER.Since the power’s flow is not constant, the sprayed ingredients become stick onto the wall of the blender, or too much or too less the ingredients become attach to the powder.

-

F.I (Front Injection) is a wet coating process in which F.I powders are sprayed from the bottom of a container and then, become dried as they are.

-

At this process, empty spherical powder (capsule powder) become filled with active agents, so when they touch the skin, the coating melts away and only the active agents are delivered onto the skin. This two-way compact is formulated for nourishing the skin from deep, rather than simple coverage.

-

While general two-way compacts are formulated with spherical powder and plate powder in an non-uniform ratio, F.I compacts are formulated with spherical powder and plate powder in a uniform ratio, in turn having the superior coverage and spreading evenly on the skin

-

General two-way compacts go through the pressurization process in which powder particles are suppressed under pressure, so they become distorted and dense and consequently, it prevents the consistent mixing with moisturizing ingredients. So they cannot be easily adhered to a puff, ending up leaving clumps on the skin.

-

Although F.I has been acknowledge for its outstanding outcome, it requires the advanced encapsulation techniques for filing liquid-phase ingredients. Especially, it requires a 48 hour drying process, causing a difficulty in both production and cost. Therefore, only a limited number of companies offer B.I two-way compacts, and they are considered to be the most advanced product.

-

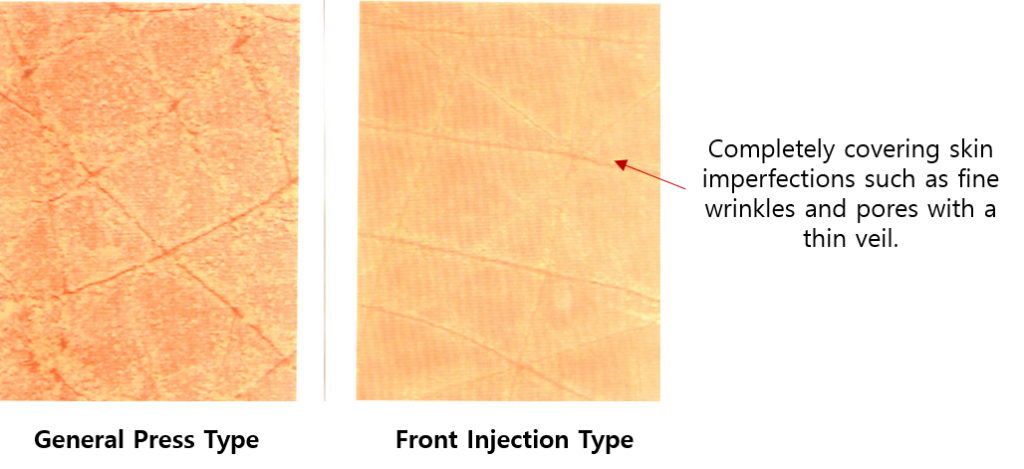

The uneven skin texture is usually a result of skin bumps, often leading to shades.

While plate powder has good adhesion, it is less spreadable, so it rather attaches onto the skin surface only. Therefore, spherical powder is used to fill the gaps in the skin, leaving the skin smooth.

-

The costs of raw materials are expected to be two to three times higher than the average.

Expected to be smooth and light, and have good skin adhesion.

Relatively weak skin coverage.

Degree of dispersion seems to be about average.

-

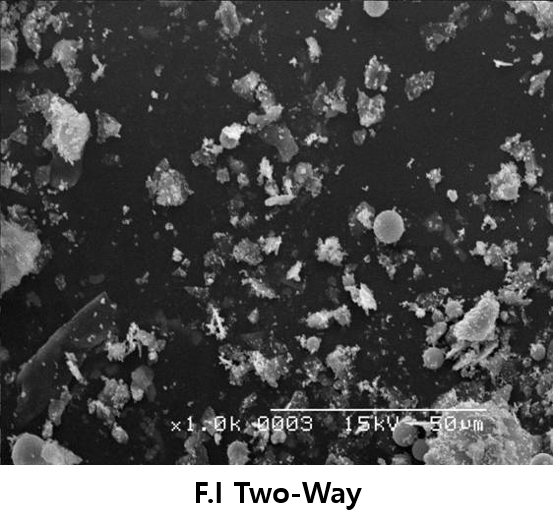

Plate powder and spherical powder are well separated, not sticking up with each other.

White clumps are 0.1~1 micro TiO2

Due to its high content of TiO2 (about 20%), its skin coverage is outstanding.

General Press Two-Way uses about 12~13%

Degree of dispersion is outstanding.

-

01‘Trend’Premium oil capsule which leads the trend

-

02‘Beauty’Can select fragrance and colors which meet buyers needs.

-

03‘Strengthening’The capsule adsorbs the base’s active ingredients and strengthens efficiency.

-

04‘Expansion’The scope of product development is wide as the ingredients that consumers want can to be infused.

-

05‘Function’Can sell products to consumers confidently Through Reliable function.

-

General Press Type Compact

It goes through the pressurization press, which exerts pressure from top onto the powder in a container.

Since pressure is exerted onto the powder, its particles become suppressed, dented, and inconsistent.

Since the particles are suppressed and dented, when the powder is applied onto the skin, it does not spread evenly on the skin, ending up being heavy.

-

Wet Coating Type Compact

Wet, moisturized powder particles become dried as they are, without the pressurization process.

Since the powder becomes dried without any pressure, its particles maintain the original shape and consistency.

Since the particles maintain the original shape and consistency, the powder spreads evenly on the skin, without creating any hint of thickness.